2017年3月11日(土)

Laser Cutting Machine Processing

Laser cutting machine is a high-tech intelligent equipment which integrates numerical control technology, laser cutting technology and inverter power supply technology. The development of laser cutting technology is based on the common progress of computer control, burning laser pen optics and power electronics. PIC system, belonging to the older board control system, can be integrated into the ordinary computer to run, the use of background software to control the analog signal transmission, the control system, although old, but are fully open system.

optics and power electronics. PIC system, belonging to the older board control system, can be integrated into the ordinary computer to run, the use of background software to control the analog signal transmission, the control system, although old, but are fully open system.

<img src="http://www.everyonetobuy.com/images/STARA-25.jpg" alt="laser pointer" width="500" />

Laser cutting machine processing as an advanced means of material cutting, has been more and more accepted by sheet metal producers. With the computer control technology and optical technology continues to progress, people for their processing capacity expectations are getting higher and higher, this expectation is not only able to cut, but also cut well and cut fast expectations. Metal laser cutting machine is a solid fiber module as a source of excitation of the metal laser output of high energy density of the laser beam, and focus on the workpiece surface, so that the workpiece area by the spot light instantaneous melting and gasification, through the computer control CNC machine The system moves the spot position to achieve automatic cutting. It is a set of 3000mw laser pointer technology, numerical control technology, precision machinery technology in one of the high-tech equipment. And can give the answer, of course, can not be separated from the performance of processing machines, while the quality of processed materials also directly affect the effectiveness of the answer.

technology, numerical control technology, precision machinery technology in one of the high-tech equipment. And can give the answer, of course, can not be separated from the performance of processing machines, while the quality of processed materials also directly affect the effectiveness of the answer.

In general, the shorter the pulse width, it is difficult to obtain high average power, therefore, from this point of view, the short pulse is at the expense of the average power at the expense. In addition, the narrower the pulse width, the greater the spectral width, therefore, the color difference will also affect the processing effect. Followed by the effect of wavelength, for the general material, the wavelength of the etching effect is not significant, only in the transparent material (such as SiO2) when the processing is considered, and should consider the wavelength problem. As mentioned earlier, transparent materials have a strong absorption of ultraviolet light, and for visible and infrared light transmission rate is very high. So it is usually the ultra-fast laser triple frequency light for processing. For tens of femtosecond lasers, the spectral width of 20nm, or even 50nm, so the third frequency efficiency is very low. While the picosecond laser can get a higher triple frequency output.

For a set of laser fine processing system, in addition to the laser, the entire system platform to build, software control is also an important issue. Any one of the shortcomings, are sufficient to affect the performance of the entire system. Laser processing is the use of light energy through the lens after focusing on the focus to achieve a high energy density, by the photothermal effect to the processing. Laser processing does not require tools, processing speed, surface deformation is small, can process a variety of materials. Use a high powered laser pointer beam to perform various materials such as punching, cutting, scribing, welding, heat treatment, etc. Some substances with metastable energy levels absorb light energy at the excitation of extraneous photons so that the number of atoms at high energy level is greater than the number of atoms in the low energy level - the number of particles is reversed, and if there is a beam of light, Energy is equal to the two can be the corresponding difference, then it will produce stimulated radiation, the output of a lot of light energy.

beam to perform various materials such as punching, cutting, scribing, welding, heat treatment, etc. Some substances with metastable energy levels absorb light energy at the excitation of extraneous photons so that the number of atoms at high energy level is greater than the number of atoms in the low energy level - the number of particles is reversed, and if there is a beam of light, Energy is equal to the two can be the corresponding difference, then it will produce stimulated radiation, the output of a lot of light energy.

Compared with the CO2 laser, the processing time of the fiber laser is significantly shorter when the power is the same, the processing material and the thickness are the same. In addition, the power consumption of fiber lasers is significantly lower than that of CO2 5000mw green laser . Typically, the efficiency of fiber lasers is greater than 35% (YLS-ECO series lasers are close to 50% efficiency), far greater than CO2 lasers. Easy to use and low maintenance, fiber lasers are ideal for metal cutting solutions.

. Typically, the efficiency of fiber lasers is greater than 35% (YLS-ECO series lasers are close to 50% efficiency), far greater than CO2 lasers. Easy to use and low maintenance, fiber lasers are ideal for metal cutting solutions.

Through the built-in lidar, send and receive back and forth the laser line, but also inxx navigation within the sweeping robot to accurately locate their own and furniture environment, automatically create a whole house 2D map, lay the foundation for full coverage clean, and through the calculation of Luban calculation, In the establishment of a good map, the initiative 1000mw green laser will be greater than 45 square meters of the region to divide, and clean each area, will insist on bow-type straight line to ensure that the cleaning without missing, consumers do not have to worry about where there is no sweep. In recent years, the frequency of sweeping machines has increased, but most of them have been deliberately avoided by the navigation function of sweeping machines. The reason is that the cost of sweeping machines is increased, but the navigation function of the sweepers has become a necessity Demand, within the sweeping machine with its powerful navigation function, in the future market within the sweeping machine prospects are very impressive.

will be greater than 45 square meters of the region to divide, and clean each area, will insist on bow-type straight line to ensure that the cleaning without missing, consumers do not have to worry about where there is no sweep. In recent years, the frequency of sweeping machines has increased, but most of them have been deliberately avoided by the navigation function of sweeping machines. The reason is that the cost of sweeping machines is increased, but the navigation function of the sweepers has become a necessity Demand, within the sweeping machine with its powerful navigation function, in the future market within the sweeping machine prospects are very impressive.

http://eyes123456.allmyblog.com/16-laser-industry-pattern.html

http://laserman123.bravesites.com/entries/general/q-switched-fiber-laser-pulse

http://www.notre-blog.com/Eyes123456/369785-nouveau-message.aspx

optics and power electronics. PIC system, belonging to the older board control system, can be integrated into the ordinary computer to run, the use of background software to control the analog signal transmission, the control system, although old, but are fully open system.

optics and power electronics. PIC system, belonging to the older board control system, can be integrated into the ordinary computer to run, the use of background software to control the analog signal transmission, the control system, although old, but are fully open system.<img src="http://www.everyonetobuy.com/images/STARA-25.jpg" alt="laser pointer" width="500" />

Laser cutting machine processing as an advanced means of material cutting, has been more and more accepted by sheet metal producers. With the computer control technology and optical technology continues to progress, people for their processing capacity expectations are getting higher and higher, this expectation is not only able to cut, but also cut well and cut fast expectations. Metal laser cutting machine is a solid fiber module as a source of excitation of the metal laser output of high energy density of the laser beam, and focus on the workpiece surface, so that the workpiece area by the spot light instantaneous melting and gasification, through the computer control CNC machine The system moves the spot position to achieve automatic cutting. It is a set of 3000mw laser pointer

technology, numerical control technology, precision machinery technology in one of the high-tech equipment. And can give the answer, of course, can not be separated from the performance of processing machines, while the quality of processed materials also directly affect the effectiveness of the answer.

technology, numerical control technology, precision machinery technology in one of the high-tech equipment. And can give the answer, of course, can not be separated from the performance of processing machines, while the quality of processed materials also directly affect the effectiveness of the answer.In general, the shorter the pulse width, it is difficult to obtain high average power, therefore, from this point of view, the short pulse is at the expense of the average power at the expense. In addition, the narrower the pulse width, the greater the spectral width, therefore, the color difference will also affect the processing effect. Followed by the effect of wavelength, for the general material, the wavelength of the etching effect is not significant, only in the transparent material (such as SiO2) when the processing is considered, and should consider the wavelength problem. As mentioned earlier, transparent materials have a strong absorption of ultraviolet light, and for visible and infrared light transmission rate is very high. So it is usually the ultra-fast laser triple frequency light for processing. For tens of femtosecond lasers, the spectral width of 20nm, or even 50nm, so the third frequency efficiency is very low. While the picosecond laser can get a higher triple frequency output.

For a set of laser fine processing system, in addition to the laser, the entire system platform to build, software control is also an important issue. Any one of the shortcomings, are sufficient to affect the performance of the entire system. Laser processing is the use of light energy through the lens after focusing on the focus to achieve a high energy density, by the photothermal effect to the processing. Laser processing does not require tools, processing speed, surface deformation is small, can process a variety of materials. Use a high powered laser pointer

beam to perform various materials such as punching, cutting, scribing, welding, heat treatment, etc. Some substances with metastable energy levels absorb light energy at the excitation of extraneous photons so that the number of atoms at high energy level is greater than the number of atoms in the low energy level - the number of particles is reversed, and if there is a beam of light, Energy is equal to the two can be the corresponding difference, then it will produce stimulated radiation, the output of a lot of light energy.

beam to perform various materials such as punching, cutting, scribing, welding, heat treatment, etc. Some substances with metastable energy levels absorb light energy at the excitation of extraneous photons so that the number of atoms at high energy level is greater than the number of atoms in the low energy level - the number of particles is reversed, and if there is a beam of light, Energy is equal to the two can be the corresponding difference, then it will produce stimulated radiation, the output of a lot of light energy.Compared with the CO2 laser, the processing time of the fiber laser is significantly shorter when the power is the same, the processing material and the thickness are the same. In addition, the power consumption of fiber lasers is significantly lower than that of CO2 5000mw green laser

. Typically, the efficiency of fiber lasers is greater than 35% (YLS-ECO series lasers are close to 50% efficiency), far greater than CO2 lasers. Easy to use and low maintenance, fiber lasers are ideal for metal cutting solutions.

. Typically, the efficiency of fiber lasers is greater than 35% (YLS-ECO series lasers are close to 50% efficiency), far greater than CO2 lasers. Easy to use and low maintenance, fiber lasers are ideal for metal cutting solutions.Through the built-in lidar, send and receive back and forth the laser line, but also inxx navigation within the sweeping robot to accurately locate their own and furniture environment, automatically create a whole house 2D map, lay the foundation for full coverage clean, and through the calculation of Luban calculation, In the establishment of a good map, the initiative 1000mw green laser

will be greater than 45 square meters of the region to divide, and clean each area, will insist on bow-type straight line to ensure that the cleaning without missing, consumers do not have to worry about where there is no sweep. In recent years, the frequency of sweeping machines has increased, but most of them have been deliberately avoided by the navigation function of sweeping machines. The reason is that the cost of sweeping machines is increased, but the navigation function of the sweepers has become a necessity Demand, within the sweeping machine with its powerful navigation function, in the future market within the sweeping machine prospects are very impressive.

will be greater than 45 square meters of the region to divide, and clean each area, will insist on bow-type straight line to ensure that the cleaning without missing, consumers do not have to worry about where there is no sweep. In recent years, the frequency of sweeping machines has increased, but most of them have been deliberately avoided by the navigation function of sweeping machines. The reason is that the cost of sweeping machines is increased, but the navigation function of the sweepers has become a necessity Demand, within the sweeping machine with its powerful navigation function, in the future market within the sweeping machine prospects are very impressive.http://eyes123456.allmyblog.com/16-laser-industry-pattern.html

http://laserman123.bravesites.com/entries/general/q-switched-fiber-laser-pulse

http://www.notre-blog.com/Eyes123456/369785-nouveau-message.aspx

2017年2月25日(土)

Fiber Laser Marking

The market is the use of the new micro fabrication technology, including advanced laser with good beam quality of the marking machine for processing, the effect is similar to the traditional processing technology, but the process is cheaper, faster and more flexible. Fiber violet laser pointer marking technology costs two to three times cheaper than traditional processing technology. Is seeking to reduce the manufacturing cost, and meet the challenges of the batch processing of small manufacturers, can use single mode fiber laser marking machine in a series of materials (including steel, nickel, titanium, silicon, aluminum and copper) to achieve good machining effect. Consider the replacement of EDM equipment manufacturers, as well as those who are considering the use of new technology may turn to 532nm and 355nm laser manufacturers, you can consider the use of fiber laser marking machine.

marking technology costs two to three times cheaper than traditional processing technology. Is seeking to reduce the manufacturing cost, and meet the challenges of the batch processing of small manufacturers, can use single mode fiber laser marking machine in a series of materials (including steel, nickel, titanium, silicon, aluminum and copper) to achieve good machining effect. Consider the replacement of EDM equipment manufacturers, as well as those who are considering the use of new technology may turn to 532nm and 355nm laser manufacturers, you can consider the use of fiber laser marking machine.

In the hands of a skilled operator, the use of fiber laser marking machine for the latest progress of micro machining, can create desired characteristics. The main advantages of this method are: fiber 1mw laser pointer marking machine is two to three times cheaper than the traditional equipment used for micro machining. The successful implementation of micro machining of small size requires not only the correct tools, but also the knowledge of how to use the tools to get the desired results.

marking machine is two to three times cheaper than the traditional equipment used for micro machining. The successful implementation of micro machining of small size requires not only the correct tools, but also the knowledge of how to use the tools to get the desired results.

The LMF2000-SM fiber laser marking machine has a very high beam quality and produces a focused spot with a diameter as low as 20 μm. It is therefore particularly suitable for scribing and cutting of various materials, including alumina, silicon, copper and aluminum foil. In addition, the use of an optional pulse width waveform with different pulse width and peak power characteristics can adjust the removal rate and processing quality of the feature surface.

Pulse width and peak power independent control, compared to the traditional Q-switched laser (which provides a fixed pulse width / peak power setting), with significant control advantages and process tuning. The fast moving laser beam scanning head is also a key part of the system, which requires sufficient high speed movement with appropriate repeatability and accuracy. Fiber burning laser pointer micromachining techniques can be used in a variety of applications, such as selective removal of solder resist layers, solar cell scribing and drilling, drilling of stainless steel for medical low carbon steel pipes and fluid flow control systems, and The rapid part prototyping produces a metal with a thickness of 0.02 inches or less.

micromachining techniques can be used in a variety of applications, such as selective removal of solder resist layers, solar cell scribing and drilling, drilling of stainless steel for medical low carbon steel pipes and fluid flow control systems, and The rapid part prototyping produces a metal with a thickness of 0.02 inches or less.

Although UV lasers provide better processing quality than fiber lasers, fiber laser processing is good enough for this particular application, and its processing quality is sufficient to meet application requirements. In addition, the fiber laser processing speed than the UV high power laser pointer 17 times faster, and its cost is only 50% of the UV laser. Due to the laser path program error, the roundness of the hole processed by the UV laser is slightly flawed.

17 times faster, and its cost is only 50% of the UV laser. Due to the laser path program error, the roundness of the hole processed by the UV laser is slightly flawed.

There are many applications that require (or benefit) the selective removal of the laser, such as the removal of metals, ceramics, and even coatings or coatings on plastics. Fiber laser processing technology has shown good processing results in the solder layer micromachining, thin film resistor / capacitor dressing, and removal of active layers in battery foils for welding purposes. This selective and custom layer removal process is usually not possible in the production of components or parts, since simply masking the area is not a viable approach.

The 10mw laser pointer is useful when selecting the exact resistance value of the circuit. When used for resistance or capacitive trimming, as part of the dynamic iteration removal and measurement adjustment process, where the removal area of each element may be different, laser processing technology in this kind of application performance is very good.

is useful when selecting the exact resistance value of the circuit. When used for resistance or capacitive trimming, as part of the dynamic iteration removal and measurement adjustment process, where the removal area of each element may be different, laser processing technology in this kind of application performance is very good.

Single-mode fiber laser marking machine is a cost-effective micro-machining workstation Single-mode fiber 5mw green laser marking machine can be used as a cost-effective micro-processing workstations for drilling, cutting and marking for a variety of applications And ablation processing. Of course, it can be used for marking! This desktop micro-machining center offers many advantages to maximize return on investment.

marking machine can be used as a cost-effective micro-processing workstations for drilling, cutting and marking for a variety of applications And ablation processing. Of course, it can be used for marking! This desktop micro-machining center offers many advantages to maximize return on investment.

It is important to note that, in addition to having the right work tools, it is more important to know how to use tools effectively and efficiently.

http://blog.udn.com/Eyes123456/93036233

http://laserman123.blog.cz/1702/remote-laser-processing-technology

http://www.newcom101.de/content/blogdetail/Laser-Cutting-for-Steel-Sheet-Processing,11511.html

marking technology costs two to three times cheaper than traditional processing technology. Is seeking to reduce the manufacturing cost, and meet the challenges of the batch processing of small manufacturers, can use single mode fiber laser marking machine in a series of materials (including steel, nickel, titanium, silicon, aluminum and copper) to achieve good machining effect. Consider the replacement of EDM equipment manufacturers, as well as those who are considering the use of new technology may turn to 532nm and 355nm laser manufacturers, you can consider the use of fiber laser marking machine.

marking technology costs two to three times cheaper than traditional processing technology. Is seeking to reduce the manufacturing cost, and meet the challenges of the batch processing of small manufacturers, can use single mode fiber laser marking machine in a series of materials (including steel, nickel, titanium, silicon, aluminum and copper) to achieve good machining effect. Consider the replacement of EDM equipment manufacturers, as well as those who are considering the use of new technology may turn to 532nm and 355nm laser manufacturers, you can consider the use of fiber laser marking machine.In the hands of a skilled operator, the use of fiber laser marking machine for the latest progress of micro machining, can create desired characteristics. The main advantages of this method are: fiber 1mw laser pointer

marking machine is two to three times cheaper than the traditional equipment used for micro machining. The successful implementation of micro machining of small size requires not only the correct tools, but also the knowledge of how to use the tools to get the desired results.

marking machine is two to three times cheaper than the traditional equipment used for micro machining. The successful implementation of micro machining of small size requires not only the correct tools, but also the knowledge of how to use the tools to get the desired results.The LMF2000-SM fiber laser marking machine has a very high beam quality and produces a focused spot with a diameter as low as 20 μm. It is therefore particularly suitable for scribing and cutting of various materials, including alumina, silicon, copper and aluminum foil. In addition, the use of an optional pulse width waveform with different pulse width and peak power characteristics can adjust the removal rate and processing quality of the feature surface.

Pulse width and peak power independent control, compared to the traditional Q-switched laser (which provides a fixed pulse width / peak power setting), with significant control advantages and process tuning. The fast moving laser beam scanning head is also a key part of the system, which requires sufficient high speed movement with appropriate repeatability and accuracy. Fiber burning laser pointer

micromachining techniques can be used in a variety of applications, such as selective removal of solder resist layers, solar cell scribing and drilling, drilling of stainless steel for medical low carbon steel pipes and fluid flow control systems, and The rapid part prototyping produces a metal with a thickness of 0.02 inches or less.

micromachining techniques can be used in a variety of applications, such as selective removal of solder resist layers, solar cell scribing and drilling, drilling of stainless steel for medical low carbon steel pipes and fluid flow control systems, and The rapid part prototyping produces a metal with a thickness of 0.02 inches or less.Although UV lasers provide better processing quality than fiber lasers, fiber laser processing is good enough for this particular application, and its processing quality is sufficient to meet application requirements. In addition, the fiber laser processing speed than the UV high power laser pointer

17 times faster, and its cost is only 50% of the UV laser. Due to the laser path program error, the roundness of the hole processed by the UV laser is slightly flawed.

17 times faster, and its cost is only 50% of the UV laser. Due to the laser path program error, the roundness of the hole processed by the UV laser is slightly flawed.There are many applications that require (or benefit) the selective removal of the laser, such as the removal of metals, ceramics, and even coatings or coatings on plastics. Fiber laser processing technology has shown good processing results in the solder layer micromachining, thin film resistor / capacitor dressing, and removal of active layers in battery foils for welding purposes. This selective and custom layer removal process is usually not possible in the production of components or parts, since simply masking the area is not a viable approach.

The 10mw laser pointer

is useful when selecting the exact resistance value of the circuit. When used for resistance or capacitive trimming, as part of the dynamic iteration removal and measurement adjustment process, where the removal area of each element may be different, laser processing technology in this kind of application performance is very good.

is useful when selecting the exact resistance value of the circuit. When used for resistance or capacitive trimming, as part of the dynamic iteration removal and measurement adjustment process, where the removal area of each element may be different, laser processing technology in this kind of application performance is very good.Single-mode fiber laser marking machine is a cost-effective micro-machining workstation Single-mode fiber 5mw green laser

marking machine can be used as a cost-effective micro-processing workstations for drilling, cutting and marking for a variety of applications And ablation processing. Of course, it can be used for marking! This desktop micro-machining center offers many advantages to maximize return on investment.

marking machine can be used as a cost-effective micro-processing workstations for drilling, cutting and marking for a variety of applications And ablation processing. Of course, it can be used for marking! This desktop micro-machining center offers many advantages to maximize return on investment.It is important to note that, in addition to having the right work tools, it is more important to know how to use tools effectively and efficiently.

http://blog.udn.com/Eyes123456/93036233

http://laserman123.blog.cz/1702/remote-laser-processing-technology

http://www.newcom101.de/content/blogdetail/Laser-Cutting-for-Steel-Sheet-Processing,11511.html

2017年2月21日(火)

The Importance of Servo Motor

Servo motor in the strongest laser pointer cutting machine is a very important component, his quality is also a direct decision on the stability of the use of equipment, especially in the deformation of the contours of the processing, it can be said to be important. In addition to its own stability, there are many external factors directly affect the normal operation of the servo motor.

cutting machine is a very important component, his quality is also a direct decision on the stability of the use of equipment, especially in the deformation of the contours of the processing, it can be said to be important. In addition to its own stability, there are many external factors directly affect the normal operation of the servo motor.

For laser cutting machine, whether it is flat or cut pipe cutting, you want the equipment in accordance with the established graphics processing, the key is to participate in the processing of the dynamic response of the various axes of the level and the coordination between each other. If the overall response of each axis is too slow during processing, or if there is a situation where the axis deviation is small and the other axis is large, the deformation of the contour will occur. There are many reasons for the occurrence of such inconsistencies, mechanical, external, servo response, control system and other factors, or multi-factor superposition. Therefore, the key to solve such problems is that each axis has good dynamic response and coordination between each other, so that it can be more strictly in accordance with established goals for burning laser pointer processing action. Servo motor as a mechanical and control system to undertake the middle of the implementing agencies, to a certain extent, make up, optimize and coordinate the action of each system to achieve a more perfect control purposes.

processing action. Servo motor as a mechanical and control system to undertake the middle of the implementing agencies, to a certain extent, make up, optimize and coordinate the action of each system to achieve a more perfect control purposes.

In addition to the stability of the servo motor itself, the external factors that affect its normal operation include:

Mechanical factors. Mechanical problems are relatively common, mainly in the design, transmission, installation, material, mechanical wear and so on.

Mechanical resonance. The greatest effect of the mechanical resonance problem on the servo is that it can not continue to improve the responsiveness of the servo motor, thus operating the device as a whole in a relatively low response state. Such problems in the synchronous belt drive machinery is more common, and other 3000mw green laser long-distance ball screw sometimes have such a situation. The main reason is the rigidity of the timing belt is low, the resonant frequency is low, the long distance of the screw itself inertia is large, and there are many deformation cases, especially in the case of small motor capacity selection is relatively easy to start vibration. At the same time the installation of the assembly process and the quality of the merits of the mechanical resonance will also have an impact.

long-distance ball screw sometimes have such a situation. The main reason is the rigidity of the timing belt is low, the resonant frequency is low, the long distance of the screw itself inertia is large, and there are many deformation cases, especially in the case of small motor capacity selection is relatively easy to start vibration. At the same time the installation of the assembly process and the quality of the merits of the mechanical resonance will also have an impact.

Mechanical jitter. Mechanical jitter is also a natural frequency of mechanical problems, usually more often appear in the single-ended fixed cantilever structure, especially in the acceleration and deceleration phase performance is particularly evident. Low-frequency jitter in the workpiece will show a large wave-like form, the higher the frequency of jitter will be jagged form.

Mechanical stress, external force and other factors. Due to the difference in mechanical material and installation, the mechanical internal stress and static friction of the drive shaft on the equipment may be inconsistent. If the internal stress or static friction of a shaft involved in the two green astronomy laser axes of the trajectory interpolation control is greater, the torque of the servo will be consumed to some extent, causing the acceleration of the shaft to slow down, resulting in processing contours Deformation. Normally we can observe the internal stress problem of the drive shaft by feedback from the servo driver.

axes of the trajectory interpolation control is greater, the torque of the servo will be consumed to some extent, causing the acceleration of the shaft to slow down, resulting in processing contours Deformation. Normally we can observe the internal stress problem of the drive shaft by feedback from the servo driver.

The effect of external forces on the shaft is also similar. The general plate cutting machine, the shaft and the workpiece is non-contact between, may be limited by the external force. But some pipe cutting machine, tube axis will participate in the cutting time of interpolation, while the other axis is generally non-contact. At this time due to the impact of the pipe by the fixture will produce a reverse force on the tube axis, so participate in interpolation control of the two-axis force situation is inconsistent, the cutting effect will certainly be affected.

Numerical control system factor. In some cases, the servo debugging brightest laser pointer effect is not obvious, this time may be involved in the adjustment of the control system. Laser cutting machine processing speed is usually relatively constant, in the straight line and the curve are the same speed. This is not a big problem in the linear motion, but in the curve, especially the small size of the arc may be due to excessive acceleration caused by contour deformation of the situation.

effect is not obvious, this time may be involved in the adjustment of the control system. Laser cutting machine processing speed is usually relatively constant, in the straight line and the curve are the same speed. This is not a big problem in the linear motion, but in the curve, especially the small size of the arc may be due to excessive acceleration caused by contour deformation of the situation.

https://laserman123.yapsody.com/event/index/62737/laser-light-source

http://hokisvisrum.org/laserman123/blog/8590/two-photon-excited-laser-scanning-real-time-stereomicroscope

cutting machine is a very important component, his quality is also a direct decision on the stability of the use of equipment, especially in the deformation of the contours of the processing, it can be said to be important. In addition to its own stability, there are many external factors directly affect the normal operation of the servo motor.

cutting machine is a very important component, his quality is also a direct decision on the stability of the use of equipment, especially in the deformation of the contours of the processing, it can be said to be important. In addition to its own stability, there are many external factors directly affect the normal operation of the servo motor.For laser cutting machine, whether it is flat or cut pipe cutting, you want the equipment in accordance with the established graphics processing, the key is to participate in the processing of the dynamic response of the various axes of the level and the coordination between each other. If the overall response of each axis is too slow during processing, or if there is a situation where the axis deviation is small and the other axis is large, the deformation of the contour will occur. There are many reasons for the occurrence of such inconsistencies, mechanical, external, servo response, control system and other factors, or multi-factor superposition. Therefore, the key to solve such problems is that each axis has good dynamic response and coordination between each other, so that it can be more strictly in accordance with established goals for burning laser pointer

processing action. Servo motor as a mechanical and control system to undertake the middle of the implementing agencies, to a certain extent, make up, optimize and coordinate the action of each system to achieve a more perfect control purposes.

processing action. Servo motor as a mechanical and control system to undertake the middle of the implementing agencies, to a certain extent, make up, optimize and coordinate the action of each system to achieve a more perfect control purposes.In addition to the stability of the servo motor itself, the external factors that affect its normal operation include:

Mechanical factors. Mechanical problems are relatively common, mainly in the design, transmission, installation, material, mechanical wear and so on.

Mechanical resonance. The greatest effect of the mechanical resonance problem on the servo is that it can not continue to improve the responsiveness of the servo motor, thus operating the device as a whole in a relatively low response state. Such problems in the synchronous belt drive machinery is more common, and other 3000mw green laser

long-distance ball screw sometimes have such a situation. The main reason is the rigidity of the timing belt is low, the resonant frequency is low, the long distance of the screw itself inertia is large, and there are many deformation cases, especially in the case of small motor capacity selection is relatively easy to start vibration. At the same time the installation of the assembly process and the quality of the merits of the mechanical resonance will also have an impact.

long-distance ball screw sometimes have such a situation. The main reason is the rigidity of the timing belt is low, the resonant frequency is low, the long distance of the screw itself inertia is large, and there are many deformation cases, especially in the case of small motor capacity selection is relatively easy to start vibration. At the same time the installation of the assembly process and the quality of the merits of the mechanical resonance will also have an impact.Mechanical jitter. Mechanical jitter is also a natural frequency of mechanical problems, usually more often appear in the single-ended fixed cantilever structure, especially in the acceleration and deceleration phase performance is particularly evident. Low-frequency jitter in the workpiece will show a large wave-like form, the higher the frequency of jitter will be jagged form.

Mechanical stress, external force and other factors. Due to the difference in mechanical material and installation, the mechanical internal stress and static friction of the drive shaft on the equipment may be inconsistent. If the internal stress or static friction of a shaft involved in the two green astronomy laser

axes of the trajectory interpolation control is greater, the torque of the servo will be consumed to some extent, causing the acceleration of the shaft to slow down, resulting in processing contours Deformation. Normally we can observe the internal stress problem of the drive shaft by feedback from the servo driver.

axes of the trajectory interpolation control is greater, the torque of the servo will be consumed to some extent, causing the acceleration of the shaft to slow down, resulting in processing contours Deformation. Normally we can observe the internal stress problem of the drive shaft by feedback from the servo driver.The effect of external forces on the shaft is also similar. The general plate cutting machine, the shaft and the workpiece is non-contact between, may be limited by the external force. But some pipe cutting machine, tube axis will participate in the cutting time of interpolation, while the other axis is generally non-contact. At this time due to the impact of the pipe by the fixture will produce a reverse force on the tube axis, so participate in interpolation control of the two-axis force situation is inconsistent, the cutting effect will certainly be affected.

Numerical control system factor. In some cases, the servo debugging brightest laser pointer

effect is not obvious, this time may be involved in the adjustment of the control system. Laser cutting machine processing speed is usually relatively constant, in the straight line and the curve are the same speed. This is not a big problem in the linear motion, but in the curve, especially the small size of the arc may be due to excessive acceleration caused by contour deformation of the situation.

effect is not obvious, this time may be involved in the adjustment of the control system. Laser cutting machine processing speed is usually relatively constant, in the straight line and the curve are the same speed. This is not a big problem in the linear motion, but in the curve, especially the small size of the arc may be due to excessive acceleration caused by contour deformation of the situation.https://laserman123.yapsody.com/event/index/62737/laser-light-source

http://hokisvisrum.org/laserman123/blog/8590/two-photon-excited-laser-scanning-real-time-stereomicroscope

2017年2月13日(月)

Laser Cutting Machine Industry Direction

In recent years, the "intelligent" competition is becoming increasingly fierce, is the birth of the great changes in the mode of manufacturing production. Chinese as a manufacturing power hardware basic conditions, but the rapid development of the industry in recent years also makes some deep problems of the accumulation of domestic brands in the international market competitiveness remains to be further strengthened. Laser cutting machine as a wide range of applications in the field of processing equipment, how to successfully transform the sprint high-end market, is a question worth pondering.

"13th Five-Year" period, the development of the industry and the domestic and international environment conditions changed significantly, is facing a major strategic opportunity to accomplish a great deal, is also facing serious challenges many contradictions superimposed on each other. On the one hand, influenced by the iron and steel industry downstream industries such as cold, burning laser cutting machine industry will be affected; on the other hand, innovation is not strong, with enterprises as the mainstay of the innovation system is not perfect. The high-end equipment industry, the core technology relies on imports. Increasing labor costs, the need to introduce equipment, transformation, improve the degree of automation, reduce dependence on labor. The state proposed along the way, made in China 2025 and other favorable policies, but also stimulate the development of the power of the laser industry. China laser cutting machine in the export may face more barriers to trade barriers, technical barriers, brand and channel barriers, which requires the keychain laser pointer

cutting machine industry will be affected; on the other hand, innovation is not strong, with enterprises as the mainstay of the innovation system is not perfect. The high-end equipment industry, the core technology relies on imports. Increasing labor costs, the need to introduce equipment, transformation, improve the degree of automation, reduce dependence on labor. The state proposed along the way, made in China 2025 and other favorable policies, but also stimulate the development of the power of the laser industry. China laser cutting machine in the export may face more barriers to trade barriers, technical barriers, brand and channel barriers, which requires the keychain laser pointer equipment of domestic manufacturing industry must accelerate the completion of structural adjustment and upgrading of the pace of transformation, change the past "Porter" extensive export mode.

equipment of domestic manufacturing industry must accelerate the completion of structural adjustment and upgrading of the pace of transformation, change the past "Porter" extensive export mode.

Improve product quality, stable product quality. Should first improve the ideological consciousness; secondly, to enhance the quality of good and stable quality is good, all cannot do without advanced manufacturing equipment; third, improve the quality must have a high quality product standards, product quality standards are rules, only high standards to guide the production of high quality. Fourth, to enhance the quality of product innovation must also be strengthened. If you want to go to power, there is no core technology is not good, no good product is not good, want to improve the competitiveness of the international market, we must enhance the sense of innovation.

Establish brand. Brand is one of the biggest green astronomy laser weaknesses in our market competition, some of our products do very well, but can not sell a good price, because the brand has not been established in the minds of consumers. The pursuit of high efficiency, high added value. Do business must have benefits, so as to sustainable development. Improve production efficiency, still rely on R & D. Improve the coordinated development of industrial chain mechanism to guide enterprises to service-oriented manufacturing transformation.

weaknesses in our market competition, some of our products do very well, but can not sell a good price, because the brand has not been established in the minds of consumers. The pursuit of high efficiency, high added value. Do business must have benefits, so as to sustainable development. Improve production efficiency, still rely on R & D. Improve the coordinated development of industrial chain mechanism to guide enterprises to service-oriented manufacturing transformation.

In addition, the femtosecond pulse can be transmitted to the end user device through optical fiber. Femtolite FD series provides fiber coupled output, repetition rate of 50MHz, average output power up to 1W. This level of pulse energy is sufficient for the use of femtosecond pulse light sources to be integrated into a wide range of nonlinear imaging or metrology applications.

Similarly, chirped pulse fiber laser amplifier (FLCPA), is the United States CalmarLaser company Cazadero high energy (up to 30 J) based ultrafast laser, the most powerful laser pointer to generate ultrafast pulse at 1 m or 1.5 m wavelength (<0.5ps), hundreds of kilohertz repetition frequency. These ultrafast laser products can output power (515nm) and ultraviolet (343nm), and Bodega and OPA coupling of the company, and then in the near infrared region (near-IR) provides a wide range of wavelengths.

to generate ultrafast pulse at 1 m or 1.5 m wavelength (<0.5ps), hundreds of kilohertz repetition frequency. These ultrafast laser products can output power (515nm) and ultraviolet (343nm), and Bodega and OPA coupling of the company, and then in the near infrared region (near-IR) provides a wide range of wavelengths.

Cazadero FLCPA ultra fast laser begins with 27MHz passive SESAM mode-locked seed fiber laser, sampling as low as 120kHz or higher. The ultrafast pulse is amplified by the frequency time (Zhou Jiu), which is amplified by a high power fiber amplifier stage with a low peak intensity. Up to 30 J short pulse energy transfer to free space. This FLCPA is a cost-effective alternative to solid state femtosecond laser amplifiers for precision biomedical materials processing and nano structured.

Because it can produce a high melting temperature higher than 4000 DEG C, synthetic materials used for melting, micro structure operation or multi material, high power femtosecond fiber amplifier has been increasingly used in material processing and manufacturing. 2014, the United States LaserFemto company for the first time to achieve a 0.5mJ femtosecond fiber Gatling laser pointer , optical fiber based femtosecond technology to improve the high power limit.

, optical fiber based femtosecond technology to improve the high power limit.

"13th Five-Year" period, the development of the industry and the domestic and international environment conditions changed significantly, is facing a major strategic opportunity to accomplish a great deal, is also facing serious challenges many contradictions superimposed on each other. On the one hand, influenced by the iron and steel industry downstream industries such as cold, burning laser

cutting machine industry will be affected; on the other hand, innovation is not strong, with enterprises as the mainstay of the innovation system is not perfect. The high-end equipment industry, the core technology relies on imports. Increasing labor costs, the need to introduce equipment, transformation, improve the degree of automation, reduce dependence on labor. The state proposed along the way, made in China 2025 and other favorable policies, but also stimulate the development of the power of the laser industry. China laser cutting machine in the export may face more barriers to trade barriers, technical barriers, brand and channel barriers, which requires the keychain laser pointer

cutting machine industry will be affected; on the other hand, innovation is not strong, with enterprises as the mainstay of the innovation system is not perfect. The high-end equipment industry, the core technology relies on imports. Increasing labor costs, the need to introduce equipment, transformation, improve the degree of automation, reduce dependence on labor. The state proposed along the way, made in China 2025 and other favorable policies, but also stimulate the development of the power of the laser industry. China laser cutting machine in the export may face more barriers to trade barriers, technical barriers, brand and channel barriers, which requires the keychain laser pointer equipment of domestic manufacturing industry must accelerate the completion of structural adjustment and upgrading of the pace of transformation, change the past "Porter" extensive export mode.

equipment of domestic manufacturing industry must accelerate the completion of structural adjustment and upgrading of the pace of transformation, change the past "Porter" extensive export mode.Improve product quality, stable product quality. Should first improve the ideological consciousness; secondly, to enhance the quality of good and stable quality is good, all cannot do without advanced manufacturing equipment; third, improve the quality must have a high quality product standards, product quality standards are rules, only high standards to guide the production of high quality. Fourth, to enhance the quality of product innovation must also be strengthened. If you want to go to power, there is no core technology is not good, no good product is not good, want to improve the competitiveness of the international market, we must enhance the sense of innovation.

Establish brand. Brand is one of the biggest green astronomy laser

weaknesses in our market competition, some of our products do very well, but can not sell a good price, because the brand has not been established in the minds of consumers. The pursuit of high efficiency, high added value. Do business must have benefits, so as to sustainable development. Improve production efficiency, still rely on R & D. Improve the coordinated development of industrial chain mechanism to guide enterprises to service-oriented manufacturing transformation.

weaknesses in our market competition, some of our products do very well, but can not sell a good price, because the brand has not been established in the minds of consumers. The pursuit of high efficiency, high added value. Do business must have benefits, so as to sustainable development. Improve production efficiency, still rely on R & D. Improve the coordinated development of industrial chain mechanism to guide enterprises to service-oriented manufacturing transformation.In addition, the femtosecond pulse can be transmitted to the end user device through optical fiber. Femtolite FD series provides fiber coupled output, repetition rate of 50MHz, average output power up to 1W. This level of pulse energy is sufficient for the use of femtosecond pulse light sources to be integrated into a wide range of nonlinear imaging or metrology applications.

Similarly, chirped pulse fiber laser amplifier (FLCPA), is the United States CalmarLaser company Cazadero high energy (up to 30 J) based ultrafast laser, the most powerful laser pointer

to generate ultrafast pulse at 1 m or 1.5 m wavelength (<0.5ps), hundreds of kilohertz repetition frequency. These ultrafast laser products can output power (515nm) and ultraviolet (343nm), and Bodega and OPA coupling of the company, and then in the near infrared region (near-IR) provides a wide range of wavelengths.

to generate ultrafast pulse at 1 m or 1.5 m wavelength (<0.5ps), hundreds of kilohertz repetition frequency. These ultrafast laser products can output power (515nm) and ultraviolet (343nm), and Bodega and OPA coupling of the company, and then in the near infrared region (near-IR) provides a wide range of wavelengths.Cazadero FLCPA ultra fast laser begins with 27MHz passive SESAM mode-locked seed fiber laser, sampling as low as 120kHz or higher. The ultrafast pulse is amplified by the frequency time (Zhou Jiu), which is amplified by a high power fiber amplifier stage with a low peak intensity. Up to 30 J short pulse energy transfer to free space. This FLCPA is a cost-effective alternative to solid state femtosecond laser amplifiers for precision biomedical materials processing and nano structured.

Because it can produce a high melting temperature higher than 4000 DEG C, synthetic materials used for melting, micro structure operation or multi material, high power femtosecond fiber amplifier has been increasingly used in material processing and manufacturing. 2014, the United States LaserFemto company for the first time to achieve a 0.5mJ femtosecond fiber Gatling laser pointer

, optical fiber based femtosecond technology to improve the high power limit.

, optical fiber based femtosecond technology to improve the high power limit.2016年12月20日(火)

Laser Excitation

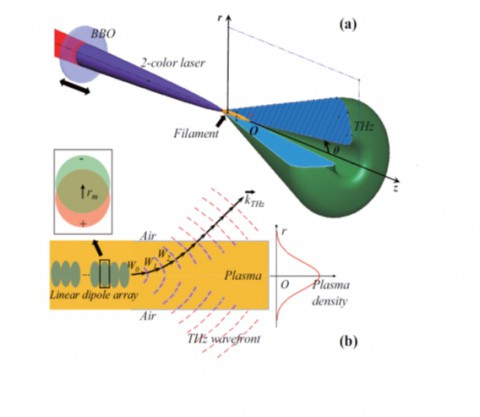

Recently, Zhang Zhelin and Chen Yanping, special associate researcher, Chen Min, and Prof. Sheng Zhengming of the Key Laboratory of Laser Plasma and Ministry of Education / IFSA Collaborative Innovation Center of Shanghai Jiaotong University made use of our laboratory KHz laser pointers device, In a controlled intense terahertz radiation.

device, In a controlled intense terahertz radiation.

Terahertz (THz) wave is located between the infrared and microwave electromagnetic radiation, is between the optical and electronics has not been widely developed band, it is in the terahertz remote sensing imaging, terahertz time-domain spectroscopy, terahertz Linear science and high-energy laser interaction with the diagnosis of substances has a great value. The strong terahertz radiation source can avoid the problem that the terahertz wave is absorbed by the water molecule when it is transported in the air, which has been paid more and more attention in recent years, because of the broadband generated by the two - color burning laser pointer field in plasma. The microscopic physical mechanism is mainly described by the ionization current model and the nonlinear four-wave mixing model. Previous studies have shown that this terahertz radiation source is a single-cycle broadband pulse. The precise manipulation of the parameters of the radiation pulse, including the radiation angle distribution, the carrier envelope phase, the pulse energy, and so on, is of great importance to its wide application.

field in plasma. The microscopic physical mechanism is mainly described by the ionization current model and the nonlinear four-wave mixing model. Previous studies have shown that this terahertz radiation source is a single-cycle broadband pulse. The precise manipulation of the parameters of the radiation pulse, including the radiation angle distribution, the carrier envelope phase, the pulse energy, and so on, is of great importance to its wide application.

By using the kilohertz laser device, the research team successfully realized the control of the single-period terahertz pulse of the radiation by controlling the length of the plasmonic fiber excited in the air and the relative phase difference of the pumped two-color high power laser pointer . Envelope phase, spatial distribution and peak intensity. Theoretically, a "linear dipole array" macroscopic model is proposed in which each part of the long filament is regarded as an independent terahertz radiation source. The far-field detected terahertz signal is the radiation of these point source arrays Coherent superposition, which is the key to explaining the generation of terahertz radiation under long-ray filament. The model well explains experimental observations and provides the basis for the generation of controllable terahertz radiation.

. Envelope phase, spatial distribution and peak intensity. Theoretically, a "linear dipole array" macroscopic model is proposed in which each part of the long filament is regarded as an independent terahertz radiation source. The far-field detected terahertz signal is the radiation of these point source arrays Coherent superposition, which is the key to explaining the generation of terahertz radiation under long-ray filament. The model well explains experimental observations and provides the basis for the generation of controllable terahertz radiation.

device, In a controlled intense terahertz radiation.

device, In a controlled intense terahertz radiation.Terahertz (THz) wave is located between the infrared and microwave electromagnetic radiation, is between the optical and electronics has not been widely developed band, it is in the terahertz remote sensing imaging, terahertz time-domain spectroscopy, terahertz Linear science and high-energy laser interaction with the diagnosis of substances has a great value. The strong terahertz radiation source can avoid the problem that the terahertz wave is absorbed by the water molecule when it is transported in the air, which has been paid more and more attention in recent years, because of the broadband generated by the two - color burning laser pointer

field in plasma. The microscopic physical mechanism is mainly described by the ionization current model and the nonlinear four-wave mixing model. Previous studies have shown that this terahertz radiation source is a single-cycle broadband pulse. The precise manipulation of the parameters of the radiation pulse, including the radiation angle distribution, the carrier envelope phase, the pulse energy, and so on, is of great importance to its wide application.

field in plasma. The microscopic physical mechanism is mainly described by the ionization current model and the nonlinear four-wave mixing model. Previous studies have shown that this terahertz radiation source is a single-cycle broadband pulse. The precise manipulation of the parameters of the radiation pulse, including the radiation angle distribution, the carrier envelope phase, the pulse energy, and so on, is of great importance to its wide application.By using the kilohertz laser device, the research team successfully realized the control of the single-period terahertz pulse of the radiation by controlling the length of the plasmonic fiber excited in the air and the relative phase difference of the pumped two-color high power laser pointer

. Envelope phase, spatial distribution and peak intensity. Theoretically, a "linear dipole array" macroscopic model is proposed in which each part of the long filament is regarded as an independent terahertz radiation source. The far-field detected terahertz signal is the radiation of these point source arrays Coherent superposition, which is the key to explaining the generation of terahertz radiation under long-ray filament. The model well explains experimental observations and provides the basis for the generation of controllable terahertz radiation.

. Envelope phase, spatial distribution and peak intensity. Theoretically, a "linear dipole array" macroscopic model is proposed in which each part of the long filament is regarded as an independent terahertz radiation source. The far-field detected terahertz signal is the radiation of these point source arrays Coherent superposition, which is the key to explaining the generation of terahertz radiation under long-ray filament. The model well explains experimental observations and provides the basis for the generation of controllable terahertz radiation.