2016年12月8日(木)

Break the Brightness Record

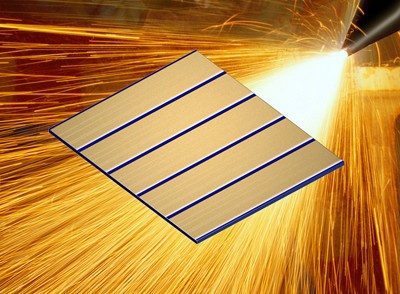

Osram Opto Semiconductors has developed a wide-area laser diode, which is reported to create laboratory brightness "records" with a lateral brightness of up to 4.8 W / (mm * mrad). The company said that the higher the brightness of the laser pointer , the more efficient the light into the fiber, so as to enhance the processing of fiber laser pumping module output power. This is one of the results of the "High Intensity Diode Laser Integrated Micro-Optics and Micro-Thermal Element" (IMOTHEB) project beginning in 2012. The project is funded by the German Federal Ministry of Education and Research and has been successfully completed.

, the more efficient the light into the fiber, so as to enhance the processing of fiber laser pumping module output power. This is one of the results of the "High Intensity Diode Laser Integrated Micro-Optics and Micro-Thermal Element" (IMOTHEB) project beginning in 2012. The project is funded by the German Federal Ministry of Education and Research and has been successfully completed.

An important application of fiber-coupled lasers is high-power lasers for pump material processing applications. For large-area laser diodes, the lateral brightness is as high as 4.8 W / mm * mrad is one of the highest values known for wide-area laser diodes. Osram OS said the optimization of chip design, in particular by integrating micro-optics and micro-thermal components on the chip to achieve beam shaping, laid the foundation for this success. These improvements were implemented in the IMOTHEB research project coordinated by OSRAM. One of the objectives of the project is to further develop 50mw laser pointer chips that enable them to achieve higher optical output power with stable beam quality. The Max Born Institute as a project partner, through the provision of a wide range of methods and analysis of the chip development work has given tremendous support. These research results will continue to integrate into product development. Pump module output power increased by 10%.

chips that enable them to achieve higher optical output power with stable beam quality. The Max Born Institute as a project partner, through the provision of a wide range of methods and analysis of the chip development work has given tremendous support. These research results will continue to integrate into product development. Pump module output power increased by 10%.

An important application of fiber-coupled lasers is to pump high-power lasers for material processing, especially fiber lasers, such as sheet metal cutting and welding of sheet metal in the automotive industry, at the same time cost pressures are increasing. As a result, the IMOTHEB project aims to reduce the system cost of such pumping modules. Project partner DILAS Semiconductor Laser Co., Ltd. developed the concept of automated assembly of diode lasers.

Another key factor is the brightness of the burning laser pointer source. DILAS uses a demonstration module to verify that the OSRAM modified version of the chip can increase the output power of the module by 10%. "Because of the high brightness of the chip, more light is injected into the fiber, and the output power of the same module is higher than the output power of laser diodes currently used in this application," explained Dr. Alexander Bachmann, project coordinator of OSRAM Opto Semiconductors.

source. DILAS uses a demonstration module to verify that the OSRAM modified version of the chip can increase the output power of the module by 10%. "Because of the high brightness of the chip, more light is injected into the fiber, and the output power of the same module is higher than the output power of laser diodes currently used in this application," explained Dr. Alexander Bachmann, project coordinator of OSRAM Opto Semiconductors.

The IMOTHEB research project aims to improve the efficiency of the 1mw laser pointer system and reduce its production costs. This project (KZ 13N12312) was launched in October 2012 and is supported by the German Federal Ministry of Education and Research (BMBF) as part of the Integrated Micro-Photonics Initiative. OSRAM Opto Semiconductors is responsible for project coordination. Other project partners are Germany's DILAS Semiconductor Laser GmbH and the Max Born Institute in Germany.

system and reduce its production costs. This project (KZ 13N12312) was launched in October 2012 and is supported by the German Federal Ministry of Education and Research (BMBF) as part of the Integrated Micro-Photonics Initiative. OSRAM Opto Semiconductors is responsible for project coordination. Other project partners are Germany's DILAS Semiconductor Laser GmbH and the Max Born Institute in Germany.

https://seenthis.net/messages/549158

https://diasp.org/posts/6457560

http://www.petite-annonce-gratuite.com/petite-annonce,520945,world,s,strongest,laser,pointer.html

, the more efficient the light into the fiber, so as to enhance the processing of fiber laser pumping module output power. This is one of the results of the "High Intensity Diode Laser Integrated Micro-Optics and Micro-Thermal Element" (IMOTHEB) project beginning in 2012. The project is funded by the German Federal Ministry of Education and Research and has been successfully completed.

, the more efficient the light into the fiber, so as to enhance the processing of fiber laser pumping module output power. This is one of the results of the "High Intensity Diode Laser Integrated Micro-Optics and Micro-Thermal Element" (IMOTHEB) project beginning in 2012. The project is funded by the German Federal Ministry of Education and Research and has been successfully completed.An important application of fiber-coupled lasers is high-power lasers for pump material processing applications. For large-area laser diodes, the lateral brightness is as high as 4.8 W / mm * mrad is one of the highest values known for wide-area laser diodes. Osram OS said the optimization of chip design, in particular by integrating micro-optics and micro-thermal components on the chip to achieve beam shaping, laid the foundation for this success. These improvements were implemented in the IMOTHEB research project coordinated by OSRAM. One of the objectives of the project is to further develop 50mw laser pointer

chips that enable them to achieve higher optical output power with stable beam quality. The Max Born Institute as a project partner, through the provision of a wide range of methods and analysis of the chip development work has given tremendous support. These research results will continue to integrate into product development. Pump module output power increased by 10%.

chips that enable them to achieve higher optical output power with stable beam quality. The Max Born Institute as a project partner, through the provision of a wide range of methods and analysis of the chip development work has given tremendous support. These research results will continue to integrate into product development. Pump module output power increased by 10%.An important application of fiber-coupled lasers is to pump high-power lasers for material processing, especially fiber lasers, such as sheet metal cutting and welding of sheet metal in the automotive industry, at the same time cost pressures are increasing. As a result, the IMOTHEB project aims to reduce the system cost of such pumping modules. Project partner DILAS Semiconductor Laser Co., Ltd. developed the concept of automated assembly of diode lasers.

Another key factor is the brightness of the burning laser pointer

source. DILAS uses a demonstration module to verify that the OSRAM modified version of the chip can increase the output power of the module by 10%. "Because of the high brightness of the chip, more light is injected into the fiber, and the output power of the same module is higher than the output power of laser diodes currently used in this application," explained Dr. Alexander Bachmann, project coordinator of OSRAM Opto Semiconductors.

source. DILAS uses a demonstration module to verify that the OSRAM modified version of the chip can increase the output power of the module by 10%. "Because of the high brightness of the chip, more light is injected into the fiber, and the output power of the same module is higher than the output power of laser diodes currently used in this application," explained Dr. Alexander Bachmann, project coordinator of OSRAM Opto Semiconductors.The IMOTHEB research project aims to improve the efficiency of the 1mw laser pointer

system and reduce its production costs. This project (KZ 13N12312) was launched in October 2012 and is supported by the German Federal Ministry of Education and Research (BMBF) as part of the Integrated Micro-Photonics Initiative. OSRAM Opto Semiconductors is responsible for project coordination. Other project partners are Germany's DILAS Semiconductor Laser GmbH and the Max Born Institute in Germany.

system and reduce its production costs. This project (KZ 13N12312) was launched in October 2012 and is supported by the German Federal Ministry of Education and Research (BMBF) as part of the Integrated Micro-Photonics Initiative. OSRAM Opto Semiconductors is responsible for project coordination. Other project partners are Germany's DILAS Semiconductor Laser GmbH and the Max Born Institute in Germany.https://seenthis.net/messages/549158

https://diasp.org/posts/6457560

http://www.petite-annonce-gratuite.com/petite-annonce,520945,world,s,strongest,laser,pointer.html

2016年11月30日(水)

The World's Largest Laser Coating Stripping Robot

Internationally renowned third-party inspection and testing organization DEKRA Dekai Group will be the world's largest innovative laser coating stripping (LCR) robot for LR Systems BV testing. Developed by LR Systems, robots will use a 20kW high power laser pointer to remove coatings from commercial and military aircraft of any size with the greatest accuracy. In addition, the robot removal process is faster and cleaner than today's methods, and can significantly reduce the aircraft stall time in the ground.

to remove coatings from commercial and military aircraft of any size with the greatest accuracy. In addition, the robot removal process is faster and cleaner than today's methods, and can significantly reduce the aircraft stall time in the ground.

"I am delighted that DEKRA will support our global LCR team," said Paul van IJsselstein, CEO of LR Systems BV. "I believe our first system development and rollout will benefit from DEKRA's unique Professional knowledge and experience, DEKRA Group's professional support can further add value to our global robotics solutions in the maintenance industry. "

DEKRA Group will be involved in the entire testing and certification process, from safety performance evaluation, component testing, and factory acceptance testing to the installation of the first LCR robot. "Our commitment to safety means that we can further enhance our commitment to innovation and high-tech services, such as EMC (electromagnetic compatibility), network security, and functionality," said Bert Zoetbrood, president of DEKRA's global laser pointer product testing and certification group. Safety and international market access. "Our support for LR Systems in the development and deployment phases of LCR robots is fully aligned with our vision and we are committed to providing innovative products at every step of the development process with globalization Of the integrated services, until the success of new products to enter the market.

product testing and certification group. Safety and international market access. "Our support for LR Systems in the development and deployment phases of LCR robots is fully aligned with our vision and we are committed to providing innovative products at every step of the development process with globalization Of the integrated services, until the success of new products to enter the market.

http://laserman12.exblog.jp/27104450/

http://laserman123.blogcu.com/the-world-s-first-commercial-space-laser-communication-system/27153446

http://www.generaccion.com/usuarios/117575/low-power-consumption-and-miniaturization-of-laser-3d-imaging-radar

to remove coatings from commercial and military aircraft of any size with the greatest accuracy. In addition, the robot removal process is faster and cleaner than today's methods, and can significantly reduce the aircraft stall time in the ground.

to remove coatings from commercial and military aircraft of any size with the greatest accuracy. In addition, the robot removal process is faster and cleaner than today's methods, and can significantly reduce the aircraft stall time in the ground."I am delighted that DEKRA will support our global LCR team," said Paul van IJsselstein, CEO of LR Systems BV. "I believe our first system development and rollout will benefit from DEKRA's unique Professional knowledge and experience, DEKRA Group's professional support can further add value to our global robotics solutions in the maintenance industry. "

DEKRA Group will be involved in the entire testing and certification process, from safety performance evaluation, component testing, and factory acceptance testing to the installation of the first LCR robot. "Our commitment to safety means that we can further enhance our commitment to innovation and high-tech services, such as EMC (electromagnetic compatibility), network security, and functionality," said Bert Zoetbrood, president of DEKRA's global laser pointer

product testing and certification group. Safety and international market access. "Our support for LR Systems in the development and deployment phases of LCR robots is fully aligned with our vision and we are committed to providing innovative products at every step of the development process with globalization Of the integrated services, until the success of new products to enter the market.

product testing and certification group. Safety and international market access. "Our support for LR Systems in the development and deployment phases of LCR robots is fully aligned with our vision and we are committed to providing innovative products at every step of the development process with globalization Of the integrated services, until the success of new products to enter the market.http://laserman12.exblog.jp/27104450/

http://laserman123.blogcu.com/the-world-s-first-commercial-space-laser-communication-system/27153446

http://www.generaccion.com/usuarios/117575/low-power-consumption-and-miniaturization-of-laser-3d-imaging-radar

2016年11月5日(土)

Discussion on Laser Welding Technology in Automobile

Laser welding using high energy density laser as the heat source in the material connection, so that the separation of material absorption of laser energy after the rapid melting and even vaporization and the formation of pool together, in the subsequent cooling process together to solidify together. Figure 1 is the tube blue laser pointer welding process, the red region is roughly the laser propagation path, high brightness of the region after the metal heat generated by vaporization of the metal vapor. See here, Tell me what can not help but ask, where the laser, how I did not see. This is because there are two common high-power lasers for laser welding: CO2 laser and solid / fiber laser, the former wavelength is 10.6μm, or the wavelength is 1.06 / 1.07μm, all in the infrared band, so the naked eye is invisible of.

welding process, the red region is roughly the laser propagation path, high brightness of the region after the metal heat generated by vaporization of the metal vapor. See here, Tell me what can not help but ask, where the laser, how I did not see. This is because there are two common high-power lasers for laser welding: CO2 laser and solid / fiber laser, the former wavelength is 10.6μm, or the wavelength is 1.06 / 1.07μm, all in the infrared band, so the naked eye is invisible of.

Laser welding mainly has the heating range centralized and precise controllable, the welding distortion is small, the welding speed is quick and so on the characteristic. In order to help you Tell me what the brain fill, we take the laser welding and common arc welding comparison. The 30mw laser pointer spot diameter can be controlled precisely. Usually, the diameter of the spot on the surface of the material is in the range of 0.2-0.6mm, and the energy near the center of the spot is exponentially decaying from the center to the edge. Weld seam width can be controlled below 2mm. The arc width of the arc can not be precisely controlled and far greater than the diameter of the laser beam, arc welding seam width is much larger than the laser welding, usually more than 6mm. As the laser welding of energy is very concentrated, so that the melting of the material less, the total heat required is small, so welding deformation is small, fast welding speed. You can write to the image of the analogy of laser welding and arc welding. Laser welding is like writing with a 0.3mm signature pen, the word must be so fine, write very quickly, finished the basic paper did not change, where it can be said to be where the fight; arc welding with a lot of brush writing, Not only thick, with the strength of the word is not the same as the thickness of the word is different, and write slowly, finished paper too much because of immersion deformation, can only say where to fight where. From the above description of laser welding we can see that the 20000mw laser pointer

spot diameter can be controlled precisely. Usually, the diameter of the spot on the surface of the material is in the range of 0.2-0.6mm, and the energy near the center of the spot is exponentially decaying from the center to the edge. Weld seam width can be controlled below 2mm. The arc width of the arc can not be precisely controlled and far greater than the diameter of the laser beam, arc welding seam width is much larger than the laser welding, usually more than 6mm. As the laser welding of energy is very concentrated, so that the melting of the material less, the total heat required is small, so welding deformation is small, fast welding speed. You can write to the image of the analogy of laser welding and arc welding. Laser welding is like writing with a 0.3mm signature pen, the word must be so fine, write very quickly, finished the basic paper did not change, where it can be said to be where the fight; arc welding with a lot of brush writing, Not only thick, with the strength of the word is not the same as the thickness of the word is different, and write slowly, finished paper too much because of immersion deformation, can only say where to fight where. From the above description of laser welding we can see that the 20000mw laser pointer welding looks like a tall welding method, then use laser welding for body welding, and the current widespread use of resistance spot welding compared to who is more high strength ?

welding looks like a tall welding method, then use laser welding for body welding, and the current widespread use of resistance spot welding compared to who is more high strength ?

The laser welded joint is a slender continuous line, as shown in Figure 2, and the resistance spot welding joint is a row of slightly concave discrete dots, as shown in Figure 3. If the laser welding joints like a zipper, like the clothes of the two lapel together, then the resistance spot welding joints like buckle buttons. Then the laser welding and resistance spot welding in the end who is more high strength? Laser welding of the weld metal is obtained through rapid solidification, and its grains (the basic composition of metal elements, can be understood as metal cells) is more small, is conducive to improving the strength of the weld metal, so the weld metal weld strength Than the resistance spot weld metal a little higher strength. At the same time do not forget, the resistance spot welding joint is a string of discrete points, just take the welding part and 10000mw laser pointer welding than have been, but those who did not weld on the place but also "drag", that average Resistance spot welding is more than laser welding. Therefore, for the same length of welded joints, the intensity of laser welding is higher than resistance spot welding.

welding than have been, but those who did not weld on the place but also "drag", that average Resistance spot welding is more than laser welding. Therefore, for the same length of welded joints, the intensity of laser welding is higher than resistance spot welding.

After the optimization of the welding parameters, the strength of the resistance spot welding joint is higher than that of the metal base metal, but the weakest part of the whole welded body is the welding heat affected zone on the base metal. In other words, the metal base metal (especially welding heat affected zone) is the weakest link, so once the body by a strong external force, the vast majority of cases are metal base metal damage, rather than welding joints. It is precisely because of the existence of the metal matrix of this short board, making the 3000mw laser pointer welding of the body and the resistance of the external body of the spot welding strength is almost no difference. Laser welding joint strength is high, but since the strength of the metal base material drag, there is no useless!

welding of the body and the resistance of the external body of the spot welding strength is almost no difference. Laser welding joint strength is high, but since the strength of the metal base material drag, there is no useless!

See here we certainly have to ask, since the laser welding can not improve the overall strength of the body, then why do some manufacturers have to spend a lot of money to introduce laser welding it? That's because laser welding has other advantages. First of all, the welding speed of laser welding is much faster than resistance spot welding. For example, 6s of the time, laser welding can weld 1m long weld, and resistance spot welding can only weld 1 point. Second, the 100mw laser pointer welding joints are continuous, naturally there will not be like the resistance spot welding joints as the problem of leakage, so you can save the process of coating the sealant.

welding joints are continuous, naturally there will not be like the resistance spot welding joints as the problem of leakage, so you can save the process of coating the sealant.

In summary, the price and configuration similar circumstances, choose the laser welding of the body is no doubt. But there is no need to pay extra for laser welding, and the 50mw laser pointer welding as an important indicator of a car or even the first indicator is even more unnecessary.

welding as an important indicator of a car or even the first indicator is even more unnecessary.

welding process, the red region is roughly the laser propagation path, high brightness of the region after the metal heat generated by vaporization of the metal vapor. See here, Tell me what can not help but ask, where the laser, how I did not see. This is because there are two common high-power lasers for laser welding: CO2 laser and solid / fiber laser, the former wavelength is 10.6μm, or the wavelength is 1.06 / 1.07μm, all in the infrared band, so the naked eye is invisible of.

welding process, the red region is roughly the laser propagation path, high brightness of the region after the metal heat generated by vaporization of the metal vapor. See here, Tell me what can not help but ask, where the laser, how I did not see. This is because there are two common high-power lasers for laser welding: CO2 laser and solid / fiber laser, the former wavelength is 10.6μm, or the wavelength is 1.06 / 1.07μm, all in the infrared band, so the naked eye is invisible of.Laser welding mainly has the heating range centralized and precise controllable, the welding distortion is small, the welding speed is quick and so on the characteristic. In order to help you Tell me what the brain fill, we take the laser welding and common arc welding comparison. The 30mw laser pointer

spot diameter can be controlled precisely. Usually, the diameter of the spot on the surface of the material is in the range of 0.2-0.6mm, and the energy near the center of the spot is exponentially decaying from the center to the edge. Weld seam width can be controlled below 2mm. The arc width of the arc can not be precisely controlled and far greater than the diameter of the laser beam, arc welding seam width is much larger than the laser welding, usually more than 6mm. As the laser welding of energy is very concentrated, so that the melting of the material less, the total heat required is small, so welding deformation is small, fast welding speed. You can write to the image of the analogy of laser welding and arc welding. Laser welding is like writing with a 0.3mm signature pen, the word must be so fine, write very quickly, finished the basic paper did not change, where it can be said to be where the fight; arc welding with a lot of brush writing, Not only thick, with the strength of the word is not the same as the thickness of the word is different, and write slowly, finished paper too much because of immersion deformation, can only say where to fight where. From the above description of laser welding we can see that the 20000mw laser pointer

spot diameter can be controlled precisely. Usually, the diameter of the spot on the surface of the material is in the range of 0.2-0.6mm, and the energy near the center of the spot is exponentially decaying from the center to the edge. Weld seam width can be controlled below 2mm. The arc width of the arc can not be precisely controlled and far greater than the diameter of the laser beam, arc welding seam width is much larger than the laser welding, usually more than 6mm. As the laser welding of energy is very concentrated, so that the melting of the material less, the total heat required is small, so welding deformation is small, fast welding speed. You can write to the image of the analogy of laser welding and arc welding. Laser welding is like writing with a 0.3mm signature pen, the word must be so fine, write very quickly, finished the basic paper did not change, where it can be said to be where the fight; arc welding with a lot of brush writing, Not only thick, with the strength of the word is not the same as the thickness of the word is different, and write slowly, finished paper too much because of immersion deformation, can only say where to fight where. From the above description of laser welding we can see that the 20000mw laser pointer welding looks like a tall welding method, then use laser welding for body welding, and the current widespread use of resistance spot welding compared to who is more high strength ?

welding looks like a tall welding method, then use laser welding for body welding, and the current widespread use of resistance spot welding compared to who is more high strength ?The laser welded joint is a slender continuous line, as shown in Figure 2, and the resistance spot welding joint is a row of slightly concave discrete dots, as shown in Figure 3. If the laser welding joints like a zipper, like the clothes of the two lapel together, then the resistance spot welding joints like buckle buttons. Then the laser welding and resistance spot welding in the end who is more high strength? Laser welding of the weld metal is obtained through rapid solidification, and its grains (the basic composition of metal elements, can be understood as metal cells) is more small, is conducive to improving the strength of the weld metal, so the weld metal weld strength Than the resistance spot weld metal a little higher strength. At the same time do not forget, the resistance spot welding joint is a string of discrete points, just take the welding part and 10000mw laser pointer

welding than have been, but those who did not weld on the place but also "drag", that average Resistance spot welding is more than laser welding. Therefore, for the same length of welded joints, the intensity of laser welding is higher than resistance spot welding.

welding than have been, but those who did not weld on the place but also "drag", that average Resistance spot welding is more than laser welding. Therefore, for the same length of welded joints, the intensity of laser welding is higher than resistance spot welding.After the optimization of the welding parameters, the strength of the resistance spot welding joint is higher than that of the metal base metal, but the weakest part of the whole welded body is the welding heat affected zone on the base metal. In other words, the metal base metal (especially welding heat affected zone) is the weakest link, so once the body by a strong external force, the vast majority of cases are metal base metal damage, rather than welding joints. It is precisely because of the existence of the metal matrix of this short board, making the 3000mw laser pointer

welding of the body and the resistance of the external body of the spot welding strength is almost no difference. Laser welding joint strength is high, but since the strength of the metal base material drag, there is no useless!

welding of the body and the resistance of the external body of the spot welding strength is almost no difference. Laser welding joint strength is high, but since the strength of the metal base material drag, there is no useless!See here we certainly have to ask, since the laser welding can not improve the overall strength of the body, then why do some manufacturers have to spend a lot of money to introduce laser welding it? That's because laser welding has other advantages. First of all, the welding speed of laser welding is much faster than resistance spot welding. For example, 6s of the time, laser welding can weld 1m long weld, and resistance spot welding can only weld 1 point. Second, the 100mw laser pointer

welding joints are continuous, naturally there will not be like the resistance spot welding joints as the problem of leakage, so you can save the process of coating the sealant.

welding joints are continuous, naturally there will not be like the resistance spot welding joints as the problem of leakage, so you can save the process of coating the sealant.In summary, the price and configuration similar circumstances, choose the laser welding of the body is no doubt. But there is no need to pay extra for laser welding, and the 50mw laser pointer

welding as an important indicator of a car or even the first indicator is even more unnecessary.

welding as an important indicator of a car or even the first indicator is even more unnecessary.2016年11月5日(土)

Fiber Laser Sensor Technology

Dr Geoffrey Cranch, a research physicist at the Optics Department at the US Naval Research Laboratory (NRL), says there is currently no US military service that uses in-situ technology to manage the structural health of its equipment. "An automated, in-situ structural health monitoring (SHM) system is able to monitor critical structural parameters such as temperature, strain, shock and crack, and to reliably detect damage before the damage reaches a critical level," he says. A sensor for detecting the acoustic emission signal associated with the occurrence and growth of the crack in near real time. Such sensors must be smaller than existing electronic products lighter, the sensitivity of a considerable or improved, smaller.

By the US Department of Naval Research Materials Science to provide part of the investment, NRL is developing a blue laser pointer sensor, the width is about hair width. During the test, the researchers installed a distributed feedback fiber laser acousto-optic sensor in a set of aluminum rivets and measured a 0.5-MHz bandwidth acoustic emission signal generated in a two-hour accelerated fatigue test, using an equivalent Of the electrical sensors.

Embedded sensors are used to solve the acoustic event of periodic "surface abrasion" of the rivet and acoustic emission from the crack information. The time-lapse imaging of the lap will allow the observed fracture to be correlated with the measured signal. In addition to crack detection, the fiber laser sensor also demonstrates the ability to measure the impact of damage and has the potential to integrate with existing fiber strain and temperature sensing systems. This provides a multi-parameter sensing capability to meet the security requirements of the SHM system and significantly reduces total cost of ownership. "Our research team has demonstrated that the fiber 10000mw laser pointer technology is capable of detecting acoustic emissions from cracks in a simulated fatigue environment, a new part of which is fiber laser technology and how it can be applied.

The acoustic signal from the crack can also be measured using a piezoelectric sensor, which has driven the existing failure prediction work. However, Cranch said piezoelectric technology because of its large geometric size and multi-channel capacity of cable, in many applications is not practical. Cranch believes the technology has great potential in areas beyond the military, where he focuses on naval platforms such as airplanes, ships and submarines, but the technology can also be used in civil aircraft as well as in bridges and buildings.

At present, no other fiber-optic sensor can match the fiber laser acoustical emission sensor in the laboratory to achieve performance. Fiber laser sensors have demonstrated comparable acoustic sensitivity to existing electrical sensors, or even higher. The system has been able to integrate multiple fiber 3000mw laser pointer sensors into a bundle of fibers. The present work is explaining useful data for acoustic emission data to calculate failure probabilities.

By the US Department of Naval Research Materials Science to provide part of the investment, NRL is developing a blue laser pointer sensor, the width is about hair width. During the test, the researchers installed a distributed feedback fiber laser acousto-optic sensor in a set of aluminum rivets and measured a 0.5-MHz bandwidth acoustic emission signal generated in a two-hour accelerated fatigue test, using an equivalent Of the electrical sensors.

Embedded sensors are used to solve the acoustic event of periodic "surface abrasion" of the rivet and acoustic emission from the crack information. The time-lapse imaging of the lap will allow the observed fracture to be correlated with the measured signal. In addition to crack detection, the fiber laser sensor also demonstrates the ability to measure the impact of damage and has the potential to integrate with existing fiber strain and temperature sensing systems. This provides a multi-parameter sensing capability to meet the security requirements of the SHM system and significantly reduces total cost of ownership. "Our research team has demonstrated that the fiber 10000mw laser pointer technology is capable of detecting acoustic emissions from cracks in a simulated fatigue environment, a new part of which is fiber laser technology and how it can be applied.

The acoustic signal from the crack can also be measured using a piezoelectric sensor, which has driven the existing failure prediction work. However, Cranch said piezoelectric technology because of its large geometric size and multi-channel capacity of cable, in many applications is not practical. Cranch believes the technology has great potential in areas beyond the military, where he focuses on naval platforms such as airplanes, ships and submarines, but the technology can also be used in civil aircraft as well as in bridges and buildings.

At present, no other fiber-optic sensor can match the fiber laser acoustical emission sensor in the laboratory to achieve performance. Fiber laser sensors have demonstrated comparable acoustic sensitivity to existing electrical sensors, or even higher. The system has been able to integrate multiple fiber 3000mw laser pointer sensors into a bundle of fibers. The present work is explaining useful data for acoustic emission data to calculate failure probabilities.

| << | >> |